|

|

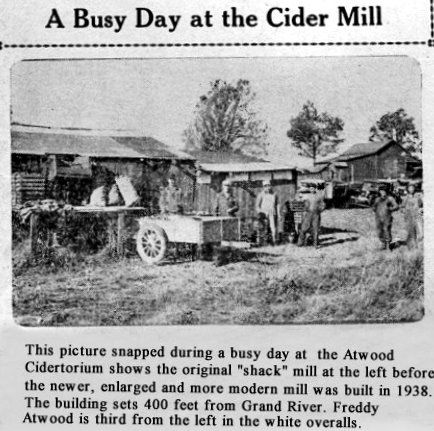

This photo of the

original Atwood's Cidertorium ran in The Laingsburg Press. A new

building to house the operation was built in 1938 and, while no longer

in business, still stands west of Laingsburg, on the south side of Grand

River, just east of the intersection with Meridian Road.

|

(Editor's Note -- A short film about Atwood's Cidertorium and

Fred Atwood will be shown during Carl Veith's presentation of this

year's Laingsburg History Day, to be held at 2 p.m. Sunday, Oct. 9, at

the St. Isidore Church fellowship hall. "Personalities" is the theme for

this year's History Day. Dorothy Witchell, Gary Craig and Mike Holder

will be headliners and relate stories about people they know who have

been instrumental in their lives. All area history buffs are invited to

attend. Any stories you would like to share that are funny,

embarrassing, daring, scary, exciting, instrumental, influential, etc.

about people you know (or have known) will be welcome. Photos and

artifacts are welcome, too. Mayo Hurst and Bill Morley will once again

join Carl as moderators.)

Atwood's Cidertorium

Halloween

witches will be swooping down upon us soon---as well as goblins,

pumpkins, costumes and CIDER. Ahh, cider and a doughnut or two. Who

could ask for anything better this time of year than a nice cold glass

of cider?

It seems just yesterday that all we needed to do was

run out to Atwood’s Cidertorium west of town and buy a gallon or two for

fifty cents each.

The cider mill still sets on the spot where it

was built on September 21, 1912 by Homer B. Atwood, but the business

(and the cider) has been long gone.

I was way too young to have

known Homer, but I well remember his son, Fred, who was 12 years old in

1912. Fred, or “Freddy” as he was more often called, was to eventually

take over the business which continued to operate for more than 50

years.

People would come from miles around not only to buy cider,

but to be entertained by the happy-go-lucky Freddy. If he was not

singing, he was dancing or telling jokes and pulling pranks. He did all

while continuing with his work-load. A favorite of his was to show the

unsuspecting customer a nice, big red apple of which he would all of a

sudden throw it on the floor and watch it bounce back up to his waiting

hands---much to the surprise of his customers who had not noticed the

switch for a red rubber ball.

Clever signs hung all around the

mill. None of the signs said anything of true importance. For instance, a

sign might read “Low Overhead” when in actuality the sign hung 10 feet

above. The signs were of various sizes and colors. Each had its own

clever saying and customers could keep themselves busy reading while

waiting for their jug of cider or for their load of apples that they had

brought in to be processed.

The original mill was just a shack

and in 1938 Freddy and his father built a new structure which was larger

and with more modern machinery. Freddy said he needed a new, catchy

name for his mill. My father, Fred W., who owned the Laingsburg Press,

suggested “Cidertorium”. Freddy liked it and the name stuck. There were

two or three other cider mills, but each had its own location and none

of them were as popular or lasted as long as Atwood’s.

Not to be

confused with a mill for the making of cider, Laingsburg has had apple

drying businesses at least three locations. One was at the south of the

old two-story school on Williams Street at the then Oscar Johnson

property. That residence was razed when Johnson sold all his land to the

school for development of the original football field (now middle

school). Another was at Railroad and Williams Streets on the southwest

corner. A third stretched just west of the depot. Not a known fact, but

reportedly the first dryer (or evaporator as owners preferred) was owned

by Daniel LeBar. It has also been said that we had three apple dryers

operating at one time.

The apple dryers were big business and

many people (mostly women) realized a good occupation for many years.

Naturally, most business was transacted in the fall.

One year

about 30,000 bushels were handled. Huge mounds of apples were piled

around the buildings. Machines pared the apples and after paring, apples

were dropped on a table where they were trimmed and sliced and placed

in vat rooms to dry. The vat rooms had large cracks in the floor and

beneath these were large open fire pots on which brimestone was placed

over hot coal.

The fumes from the burning brimestone bleached the

apples white and dried them at the same time. Nothing was wasted! The

evaporated apples were placed in cloth sacks. The parings were used for

making dyes and apples too small to be pared were put into machines to

be chopped to be used for making mincemeat.

Many people worked

for Freddy, but three I remember most is/were brothers Glen and Gary

Hagerty and Jerry Austin. Jerry lived next door with his parents, Derwin

and Elsie Austin (nee Phelps). Elsie is a direct descendant of Mason

Phelps, son-in-law of Peter Laing. Elsie resides at Walters subdivision.

Jerry

and wife, Joanne (Brewster) purchased the Atwood property and

constructed a new home, but chose to discontinue operation of the mill.

When

entering the new building, the first thing you would see was the large

apple press complete with the many belts and gears. To the immediate

left was the apple press.

Wooden frames about six or eight inches

high and approximately three or four feet square would be stacked

several high after first applying a special cloth in each frame. The

“cloth” would then be folded over four ways from each direction on top

of the apples.

When the required amount of framed apples was

ready, pressure would be applied via the press and customers would watch

with mouth-watering anticipation as the fresh juice ran into a square

stainless steel container. This vat had coasters and a valve at the

bottom so the juice could be released by hand. Freddy would pass out

samples and patrons either had their jugs filled that they had brought

with them or in glass gallon jugs sold by Freddy. In the earlier days of

Homer, the cider sold for 12 cents a gallon. I remember the cost was 50

cents per gallon.

After the juice was extracted, the load of

frames would be wheeled on a track at upper level and each would be

relieved of its load of skins by dumping out an open door. At times the

pile of skins would build to great heights before being hauled away.

Freddy always bragged that you could eat off the floor of his mill. Indeed you could!

The

stainless steel vats were cleaned regularly as were strainers, pails

and other equipment. He always preached that nothing was to ever hit the

floor---as if it would matter because of the cleanliness. Each year he

gave the place another coat of paint in apple colors---red, green and

yellow.

The Cidertorium had a capacity of 50 barrels a day. He

processed about 50,000 gallons a year and in his 50 years in business he

estimated 2,5000,000 gallons produced.

His entertainment prowess

came naturally because he also had his own band and he was an

accomplished billiards player. In his band, he played the drums and his

billiards playing began at age 10 when an uncle taught him the game. He

entered tournaments and exhibitions all over the country. He competed

with “big names” such as professional billiards Hall of Famer Willie

Mosconi. He did not always lose to them either. Never take Freddy on in a

“sure fire” billiards bet because you would always lose.

Every

fall carloads of school kids and their teachers would come from miles

around to partake of the cider and witness the antics of Freddy Atwood.

I

have said many times that “some things change and some things should

never change“. The Cidertorium and Freddy Atwood is in the “never

change” category.